Cupping Calibration in the Coffee Industry: Speaking the Same Sensory Language

By Luz Stella Artajo Medina

Coffee is one of the most chemically complex beverages we consume, with hundreds of aromatic compounds contributing to its flavor. The growing diversity of flavor profiles has attracted new audiences and expanded consumer expectations. This complexity makes both calibration and alignment essential; calibration ensures evaluators reference the same sensory standards, while alignment ensures their subjective scores are comparable. Without shared protocols and training, evaluations risk becoming inconsistent or overly subjective.

In recent decades, the way coffee is perceived and evaluated has changed dramatically, with greater attention to sensory science, standardized language, and traceability—both for consumers and for the professionals responsible for assessing its quality.

This article explores why professional cupping must go beyond personal preference, emphasizing the role of training, calibration, and continuous learning in ensuring consistent, reliable evaluations. It examines the balance between objective assessment and subjective experience—known as intersubjectivity—and how intercalibration practices help minimize differences between evaluators. Finally, it considers how these practices support alignment across the supply chain, from producers to importers to roasters, enabling the industry to meet evolving market and consumer demands.

IMPORTANCE OF PROFESSIONAL EVALUATION

For more than 20 years, the Specialty Coffee Association (SCA) cupping form and the Coffee Quality Institute (CQI) Q Grader certification—which became an SCA program in 2025—have provided widely used frameworks for evaluating coffee quality. While not industrywide standards, they established clear protocols and a shared language to describe and score coffees, allowing evaluators across many organizations to work with comparable reference points. Recently, new tools such as the Coffee Value Assessment (CVA) are prompting the industry to reconsider how evaluation and alignment are applied, balancing traditional scoring with evolving approaches to describing value.

To accurately evaluate the attributes that define coffee quality—a process centered around complexity (the more positive and intense the attributes, the higher the final score)—cuppers must be trained and experienced in this standardized approach.

“Training cuppers and tasters should include methods of quality control to protect against upstream defects and manage downstream flavor profiles that affect consumer experiences,” says Spencer Turer, vice president of Coffee Enterprises, an independent testing laboratory and consultancy specializing in coffee and tea.

In contrast, a common informal response in the industry is: “The best coffee is the coffee you like.” While this perspective may be valid from a consumer standpoint, it lacks the rigor and professionalism required for quality control. As Turer puts it, “The best coffee is the one that sells.”

In the food industry, taste panels are key in production departments, where sensory deviations are most likely to occur. This raises key questions, such as who should be part of the panel, and what specific sensory skills and qualifications are required to become a panelist?

ROLE OF TRAINING AND CALIBRATION

The accuracy and efficiency of a sensory panel depend strictly on having the right evaluators—individuals who are screened, trained, and experienced enough to detect differences in odor, flavor, and appearance. With proper training and calibration, inconsistent results in sensory analysis can be avoided.

Maintaining quality standards within food manufacturing is crucial for companies to respond to market needs. The coffee industry is no exception. Imagine quality control and product development being based only on personal preference, with the assessor acting more like a consumer during cupping sessions—whether for accepting or rejecting products, or for describing and scoring coffees to offer a differentiated product.

“The process of cupping and grading is to accurately measure the quality of coffee offered for purchase or manufactured and ready for sale,” says Turer. “The decision for acceptability should be made based on specifications or customer expectations, not personal preferences. It’s wonderful if you like the coffee, but it’s better if the customers like it.”

Now imagine a sensory evaluator unable to detect defects, unable to recognize an aged coffee, or unable to describe the full spectrum of aromatic descriptors and attributes such as acidity, sweetness, mouthfeel, balance, and overall quality. Would that evaluation be reliable? Would it represent the company standards and portfolio?

These scenarios highlight just a few of the critical reasons it is so important to select and train evaluators with strong sensory skills and capabilities. Continuous training provides credibility, builds confidence, and proves the competency of those responsible for product evaluation. This is especially important because evaluators are often in direct communication with clients, and business decisions depend heavily on coffee characteristics.

OBJECTIVITY, SUBJECTIVITY, AND INTERSUBJECTIVITY

Over the past few decades, official certification for coffee evaluators—known as cuppers—and their calibration have been tied to the creation and use of a common language. This language allows evaluators to assess the raw material (green coffee) and, in turn, better understand the product and its framework in terms of quality.

“The goal was greater efficiency in the supply chain, to communicate quality between buyers and sellers, to help prevent rejections because coffee was evaluated differently and judged differently,” says Turer. “Before the Q program, cupper training was in the form of customized mentorships and apprenticeships at each company.”

Objectivity was often questioned with the argument that subjectivity is always present when evaluating coffee, especially when scoring the overall attribute. This became a way to justify differences when cuppers were not formally trained, not properly selected, or lacked experience. Yet objectivity and market preferences are not in opposition. Science and human perception can work together to define quality in both qualitative and quantitative terms, while coffees categorized in different quality ranges can still reach diverse markets.

This is exactly where the term intersubjectivity—introduced to the coffee industry a few years ago in the context of sensory assessment—becomes relevant. In coffee, intersubjectivity “refers to the shared understanding and agreement on quality among different stakeholders, particularly in the context of coffee cupping and evaluation,” according to A System to Assess Coffee Value, published by the SCA in 2024. It emphasizes the interactive and interpretive nature of relationships within a specific time and context.

This concept implies a balance between objective quality evaluations and preferences influenced by culture and other individual biases. It offers a path toward consistency in the specialty coffee market while still considering consumer preferences.

Consistency is, without a doubt, a crucial point in the specialty coffee market. This is where calibration gains relevance worldwide. Training and continuous learning about coffee and its sensory expression—shaped by genotype, terroir, and processing—create true expertise. Those responsible for coffee evaluations must be experts.

“The value of a quality measurement system is the standardization of the method of analysis,” Turer says. “When we test the coffee similarly, the variations of flavor characteristics are judged to determine the quality of the coffee, without the quality being influenced by the testing process.”

CALIBRATION AND INTERCALIBRATION PRACTICES

Understanding consumer behavior is essential for connecting with audiences and tailoring offerings to diverse palates. Consumer preferences are shaped by personal factors such as background, psychology, perception, and attitude, as well as social factors including trends and expectations—which have been particularly influential in the specialty coffee market over the past decade, highlighting the need to align quality control with market demands.

Is cupper calibration still required, or is evaluation now simply based on preference? While debates continue, research shows that professional cuppers can produce reliable descriptive results after just a few hours of training. Still, professional cupping evaluators require much more: ongoing training, a deep understanding of coffee attributes, and adherence to specific protocols. This level of expertise takes years to develop and even longer to master.

The concept of intercalibration should be incorporated into the vocabulary of coffee sensory analysis to promote a more inclusive and holistic perspective on objective assessments. If we integrate “value” into coffee assessment, then let us also add value to the system by ensuring that experts (trained and experienced cuppers) are a strategic part of it.

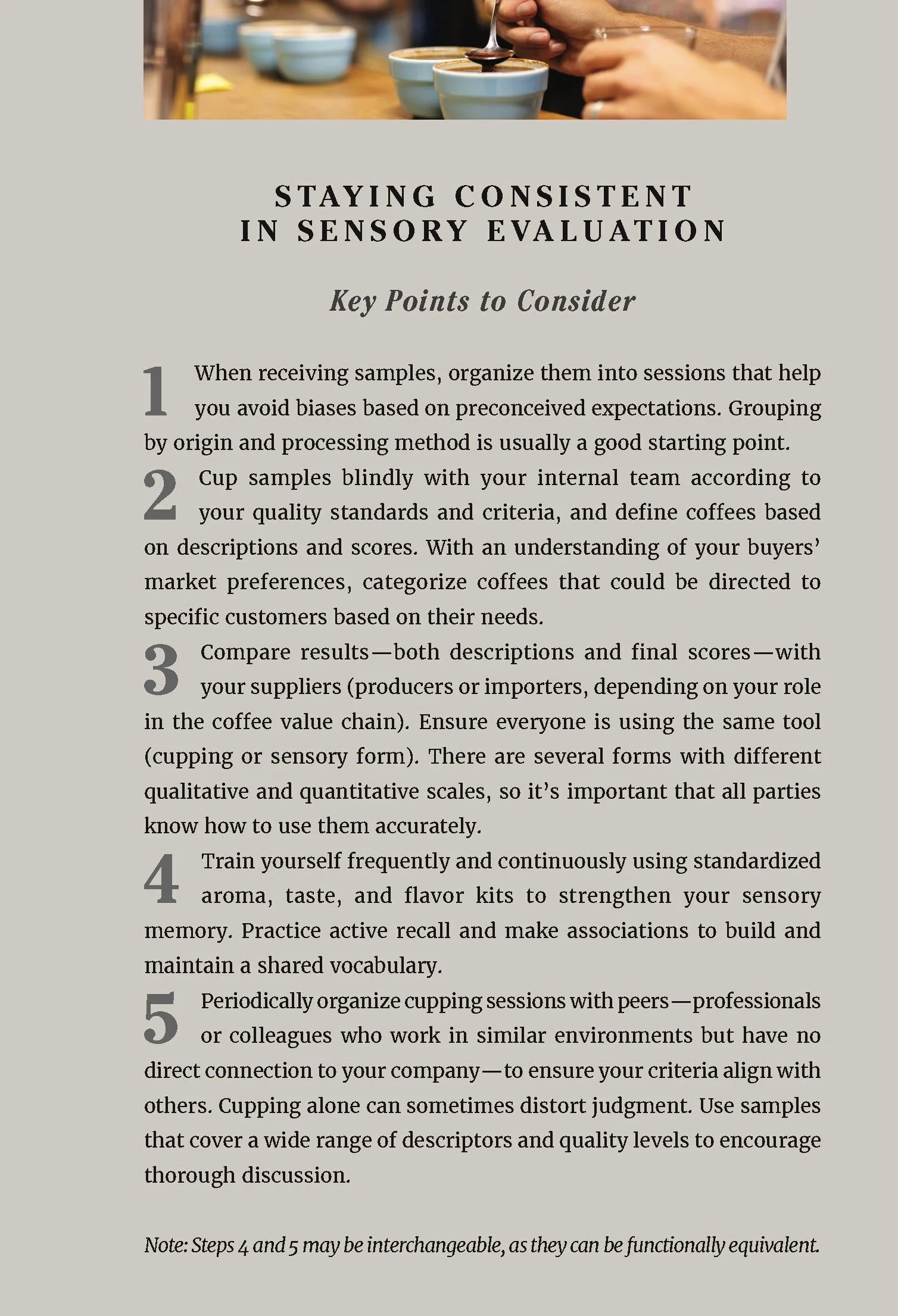

Intercalibrations are conducted mainly to minimize individual differences, ensuring that all evaluators understand the aspects being measured, the scales used to define quality, and the qualitative descriptors that support a score.

To maintain credibility, intercalibration follows rigorous procedures such as:

Training: Using standardized procedures and protocols.

Reference Materials: Tools that calibrate perception with common terms.

Performance Monitoring: Assessors’ results are tracked and compared against the group.

Statistical Analysis: Evaluating differences among assessors and adjusting descriptors and scores.

Proficiency Testing: Ensuring consistency across distinct assessor groups.

Tasting coffees by a group of assessors may not follow the same structure as a trained sensory panel, yet in some contexts it can still provide useful alignment. For example, assessments that bring together producers, green buyers, importers, and roasters allow opinions to be shared in the same environment. (A “group of assessors” generally refers to cuppers gathered for evaluation without formal selection or performance verification, whereas a “trained sensory panel” consists of screened, trained evaluators whose sensory accuracy and consistency are routinely tested.)

Conversely, when cupping coffees with a defined purpose and clear criteria—assessing both positive and negative attributes in qualitative and quantitative terms—calibration is essential. From there, results can be connected to marketing departments to guide products toward the right consumers.

“The goal of the cupper or taster is the unbiased and accurate evaluation and conclusion for the descriptive analysis and quality judgment of the coffee, producing an actionable analysis report that can be used by purchasing, manufacturing, and marketing to make appropriate business decisions,” Turer says.

This concept applies not only to small cupping groups, such as quality managers at origin or green buyers within a company. These groups may establish internal guidelines, but they should not operate in isolation. Intercalibration ensures the industry continues to speak the same language, with trained cuppers around the world evaluating coffees under recognized standards and statistical frameworks.

Calibration in the coffee industry must consider consistency (minimizing personal bias), reproducibility (achieving similar results when the same product is evaluated in different locations and by different sensory panelists), reliability (strengthening data accuracy when multiple cuppers evaluate a sample), and comparability (understanding how different professionals apply common criteria to the same coffee).

“Consistency is challenging without working regularly to maintain alignment,” says Turer. “Cuppers and company sensory panels operate individually by the nature of their location. Lack of regular interaction and side-by-side cupping leads to scores drifting out of alignment. To ensure similar conclusions are reached on quality among different stakeholders in the supply chain, and for different roasteries in a company or among different roasteries for a private label brand, regular side-by-side cupping or shared samples must be used for training and to verify quality determinations are the same.”

ALIGNMENT ACROSS THE SUPPLY CHAIN

Green importers and roasters, who work daily with both quality and market preferences, bring valuable expertise. Their perspectives help illuminate the current realities of the coffee industry and ensure that evaluation remains both professional and relevant.

In the following Q&A, Miranda Ciarfuglia of Delicoffee Trade in Valencia, Spain, gives us an idea of how the leaders of coffee business corporations—such as the company she runs along with her sister, Veronica Ciarfuglia—understand sensory evaluation and its application in their daily work:

How are companies calibrating across different sites today?

Ciarfuglia: In our position as green coffee importers, communication with both clients and suppliers is essential. In our lab, we receive samples and always cup them blind to ensure maximum objectivity. As two Q Graders, we compare our notes and then check them against the information provided by suppliers. However, when two cuppers work side by side each day, their scores can drift together as they unconsciously adapt to each other’s judgments. Regular calibration with suppliers and customers helps prevent this drift.

Cuppers who work closely often develop shared language and similar quality judgments, which can unintentionally narrow panel diversity. The most effective sensory panels include evaluators with different levels of acuity and sensitivity, all capable of accurately describing coffees according to their perceptions. Alignment should exist at the level of primary and secondary flavor categories on the SCA Coffee Taster’s Flavor Wheel, while the panel leader is responsible for identifying outliers or sensory gaps among cuppers.

Naturally, there can be slight differences in results, since language and cultural background influence perception. Yet when trained cuppers use the same system, results tend to be very close, and the language remains consistent. Alignment helps ensure that quality judgments are not driven by cultural or geographical preferences. When traders understand customer preferences, accurate quality evaluations help match coffees to appropriate markets without bias.

Clients often request a technical cupping sheet, which we provide as an average of our evaluations. We are clear that these are our notes and interpretations. This is the only way to maintain clear and coherent communication throughout the chain.

How are the systems and tools for sensory evaluation evolving?

Ciarfuglia: The shared language of the SCA cupping form continues to serve professionals. For two decades, it has allowed clients—even those who don’t cup themselves—to interpret quality through our descriptions. This common framework supports professional communication and purchasing decisions. The challenge is that the Q Grader program is evolving, and professionals now ask, “How will we evaluate quality in the future?” While the SCA cupping form remains valuable for professional exchange, it is designed for trained and, ideally, certified cuppers. There is risk in using sensory scales without sufficient training, as unreliable data can lead to inconsistent quality decisions. The new SCA CVA and similar tools are intended for qualified professionals, so the industry may need to retain this professional framework while also developing more accessible tools for broader audiences. Formats like Cup of Excellence remain valid but serve a different role—they highlight competition coffees rather than everyday trade quality.

What does “calibration/alignment” look like in real-world scenarios between producers, buyers, and roasters?Ciarfuglia: Alignment across the supply chain happens when all parties share a clear understanding of the expected cup profile. Producers communicate their processes, importers verify and confirm quality, and roasters make decisions based on both preferences and customer needs.

Sometimes roasters use formal cupping formats. Other times, they rely on more intuitive approaches. In this context, the new CVA format could be especially useful. It is intuitive, shifts focus away from a single score, and instead emphasizes descriptors that communicate the qualities of a coffee. This allows for informed decisions without being constrained by numbers.

Ultimately, alignment depends on speaking the same language and recognizing that different markets and countries prioritize different profiles. What matters most is that everyone in the chain clearly understands the qualities being described.

MARKET AND CONSUMER CONSIDERATIONS

A lack of knowledge about processing methods, combined with an incomplete understanding of coffee profiles, can lead to subjective and inconsistent evaluations—especially when analytical methods are not followed appropriately or when cuppers are not fully trained. In blind analysis, provenance, processing method, and variety should not influence quality assessment. Trade associations do not regulate coffee quality; rather, they provide education and shared frameworks for collaboration. Each company remains responsible for its own operational standards and purchasing decisions.

Arguments for assessing coffee based on subjective impressions of quality are now more common. This includes affective assessments within tools such as the CVA, where a single cupper’s impression of quality may not align with others at the same table. Historically, cuppers in producing and consuming countries aligned their scoring systems to ensure shared understanding—minimizing translation errors and helping the right coffees reach the right buyers. This makes the role of experts more important than ever. Professionals in the coffee industry must be qualified, proficient, and knowledgeable when submitting evaluation reports at origin, and when translating and communicating those results for diverse markets. Establishing partnerships is central to coffee dynamics. Quality does not conflict with market demand; rather, understanding the market allows different quality products to find their places.

Consumers will always express their judgments, and their opinions must be heard. However, the broader responsibility for understanding the coffee value chain falls to professionals with scientific training and credibility. These individuals must continually develop their skills and be regularly evaluated for performance. Expertise makes a significant difference in sensory analysis.

RELIABILITY AND CONSISTENCY ARE KEY

All actors in the supply chain can taste coffee and share opinions that enrich market understanding. But true alignment depends on trained assessors, and even a basic level of training can improve reliability, though the purpose of the assessment always matters.

Experience shows that the most reliable results come when expert cuppers, despite differences in background and culture, follow the same protocols and standards. Their assessments are grounded in years of training and constant evaluation, forming the backbone of quality control across the coffee industry.

* * *

LUZ STELLA ARTAJO MEDINA is a food engineer with a Ph.D. in food technology and master’s degrees in coffee economics and international business. Since joining the coffee world in 2007 as a Cup of Excellence auditor in Colombia, she has worked with CQI as a regional coordinator and consultant and is a Q Instructor and Q Processing Expert. Recognized as CQI’s 2022 Distinguished Instructor, she has trained cuppers and advised processing projects across Colombia and globally, helping farmers elevate coffee quality through science-based practices.

Advertisement